Enhanced Real-Time Communication for Seamless Robotic Operations

Real-time Communication Enhancements

Modern workplaces demand fluid interactions, and real-time communication (RTC) technologies are rising to meet this challenge. The need for instantaneous collaboration has fundamentally altered how teams operate globally, with RTC serving as the backbone of this transformation. Unlike traditional methods, today's solutions focus on creating natural, interruption-free dialogues.

Beyond basic voice and video, contemporary RTC platforms incorporate intelligent features that adapt to user behavior. These innovations prove particularly valuable for distributed teams who rely on virtual spaces to maintain productivity across time zones.

Improved Audio and Video Quality

Cutting-edge noise suppression algorithms now eliminate distracting ambient sounds, allowing participants to focus solely on the conversation. This technological leap has removed one of the major pain points for professionals working from dynamic environments like home offices or co-working spaces.

Video transmission has seen parallel improvements, with adaptive bitrate streaming ensuring stable connections even on mobile networks. The result? Virtual meetings that feel nearly as natural as face-to-face interactions, with minimal lag or distortion.

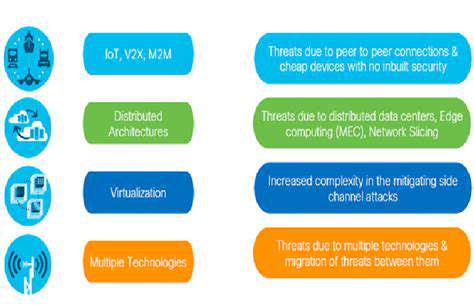

Enhanced Security Measures

With sensitive business discussions moving online, end-to-end encryption has become non-negotiable for professional communication platforms. Modern RTC solutions employ military-grade protocols to protect data integrity from endpoint to endpoint.

Multi-factor authentication and advanced intrusion detection systems provide additional layers of protection. These comprehensive security measures give organizations confidence when discussing proprietary information through digital channels.

Integration with Other Platforms

The true power of modern RTC emerges when it seamlessly connects with productivity suites and specialized business applications. This interoperability eliminates the need for constant app switching, creating a unified workspace where communication flows naturally within existing workflows.

APIs now allow RTC features to embed directly into CRM systems, project management tools, and even custom enterprise applications. This deep integration represents a paradigm shift in how professionals collaborate across different software ecosystems.

Scalability and Reliability

Enterprise-grade RTC solutions demonstrate remarkable elasticity, automatically scaling to accommodate fluctuating user loads without perceptible performance degradation. Cloud-based architectures distribute processing loads efficiently across global server networks.

Redundant systems with automatic failover capabilities maintain service continuity even during infrastructure disruptions. This reliability proves critical for businesses that cannot afford communication breakdowns during crucial operations.

User Experience Enhancements

Contemporary interfaces prioritize intuitive design, minimizing learning curves while maximizing functionality. Customizable dashboards allow users to tailor their communication environment to personal preferences and specific job requirements.

Intelligent features like automated meeting transcriptions and real-time language translation remove traditional barriers to global collaboration. These thoughtful touches demonstrate how user-centric design principles are shaping the evolution of RTC platforms.

Precision and Efficiency in Complex Manufacturing Processes

Improving Production Through Precision

Modern manufacturing demands microscopic accuracy, particularly in advanced sectors like semiconductor production. The integration of 5G technology enables real-time quality control at unprecedented levels, with sensors detecting variances measured in microns. This hyper-precision reduces material waste significantly while improving final product consistency.

Closed-loop systems powered by 5G connectivity allow for instantaneous adjustments during production runs. This dynamic response capability represents a quantum leap over traditional batch-based quality control methods.

Optimizing Processes for Efficiency

Smart factories leverage 5G's bandwidth to implement just-in-time manufacturing protocols with remarkable precision. Production lines automatically reconfigure based on real-time demand signals, minimizing idle time and maximizing asset utilization.

Enhanced Communication and Collaboration

5G networks dissolve communication barriers between production teams, quality control specialists, and supply chain managers. Shared augmented reality interfaces allow geographically dispersed experts to collaborate on complex assembly processes in real time.

Real-Time Monitoring and Control

The sub-10ms latency of 5G enables genuinely responsive manufacturing systems. Robotic arms can now make micro-adjustments mid-operation based on instantaneous sensor feedback, a capability that dramatically improves first-pass yield rates.

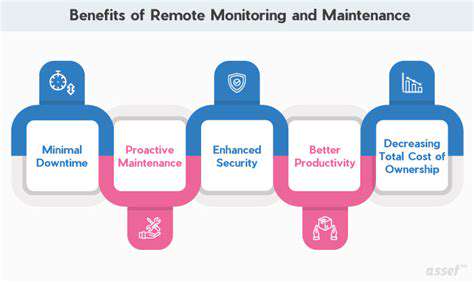

Predictive Maintenance and Proactive Solutions

Vibration analysis and thermal imaging sensors connected via 5G can predict equipment failures weeks before they occur. This foresight allows manufacturers to schedule maintenance during planned downtime, avoiding costly production interruptions.

Data-Driven Decision Making

5G-enabled factories generate terabytes of operational data daily. Advanced analytics platforms process this information to identify optimization opportunities invisible to human observers, from subtle energy inefficiencies to minor process variations.

5G and the Future of Manufacturing

The manufacturing sector stands at the threshold of a connectivity revolution. As 5G networks mature, we'll see fully autonomous factories capable of self-optimization, with production lines that reconfigure themselves based on real-time market demand and supply chain conditions.

Enabling Collaborative Robots (Cobots) and Advanced Automation

Introduction to Collaborative Robots (Cobots)

The latest generation of cobots represents a fundamental shift in human-machine interaction. Unlike their isolated industrial counterparts, these intelligent machines work in harmony with human teams. Their adaptive force-limiting mechanisms and responsive programming make them ideal partners in dynamic work environments where tasks frequently change.

Key Features of Cobots

Modern cobots incorporate advanced tactile sensors that detect human presence and adjust movements accordingly. This sensory sophistication allows safe operation in crowded workspaces without protective cages or complex safety systems, significantly reducing implementation costs.

Cobot Applications in Manufacturing

From precision assembly in electronics to delicate packaging in food processing, cobots demonstrate remarkable versatility. Their ability to learn through demonstration makes them particularly valuable for small-batch production where reprogramming traditional robots would be cost-prohibitive.

Advantages of Using Cobots

The economic case for cobots grows stronger as they become more capable. By handling repetitive strain-inducing tasks, they reduce workplace injuries while allowing human workers to focus on value-added activities that require judgment and creativity. Their quick deployment also provides manufacturers with unprecedented flexibility.

Cobot Programming and Integration

Innovative programming methods like hand-guiding and augmented reality interfaces have democratized cobot implementation. Shop floor workers without coding expertise can now train cobots for new tasks in minutes rather than days, dramatically shortening ROI timelines.

Safety Considerations for Cobot Use

While inherently safer than traditional robots, cobots require thoughtful workspace design. Proper lighting, clearly marked collaboration zones, and regular system verification ensure safe long-term operation. Ongoing operator training remains crucial as cobot capabilities continue evolving.

Future Trends in Cobot Technology

The next generation of cobots will incorporate advanced machine vision and contextual awareness. These developments will enable true symbiotic relationships where humans and machines intuitively understand each other's intentions and work patterns, creating workplaces where biological and artificial intelligence complement each other seamlessly.