The Rise of Connected Systems

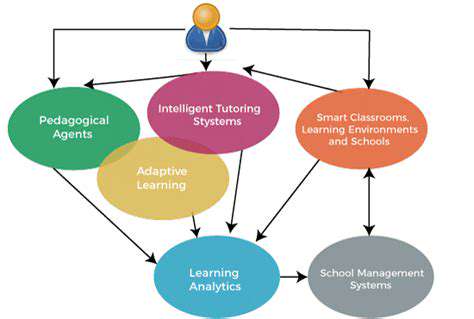

Industry 4.0, often described as the fourth industrial revolution, is fundamentally changing the way manufacturing and production are carried out. At its core lies the concept of interconnected systems. This interconnectedness allows for real-time data exchange and analysis across various stages of the production process, from raw materials to finished goods. This continuous flow of data enables businesses to make more informed decisions, optimizing efficiency and productivity.

The integration of various technologies, such as the Internet of Things (IoT), cloud computing, and advanced analytics, is crucial to achieving this interconnectedness. These technologies facilitate the collection, processing, and interpretation of data from different sources, providing a holistic view of the production process.

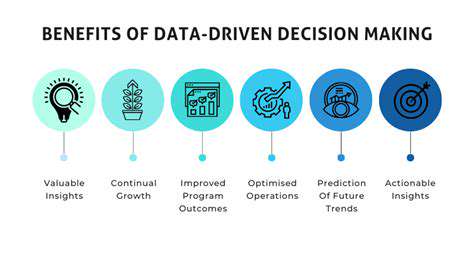

Data-Driven Decision Making

One of the most significant benefits of Industry 4.0 is the ability to make data-driven decisions. The vast amount of real-time data collected from connected systems allows businesses to identify trends, predict potential problems, and optimize processes in ways never before possible. This data-driven approach translates into improved efficiency, reduced downtime, and enhanced overall profitability.

By analyzing this data, companies can gain valuable insights into areas for improvement, allowing them to adjust production strategies in real-time. This agility is a key advantage in today's rapidly changing market landscape, enabling businesses to respond quickly to evolving demands and emerging opportunities.

Predictive maintenance is another prime example. By monitoring equipment performance and identifying patterns, companies can proactively address potential failures before they occur, minimizing downtime and maximizing equipment lifespan. This is a powerful illustration of how Industry 4.0 promotes proactive rather than reactive solutions.

Automation and Enhanced Productivity

Automation plays a critical role in the transformation brought about by Industry 4.0. The integration of robots, automated guided vehicles, and other advanced automation technologies significantly enhances productivity and efficiency in manufacturing processes. This automation allows for faster production cycles, reduced human error, and increased output, ultimately contributing to a more streamlined and cost-effective production line.

This increased automation also frees up human workers to focus on more complex and creative tasks, such as design, innovation, and quality control. The collaboration between human intelligence and automated systems is a hallmark of Industry 4.0, leading to a more efficient and effective workforce.

The emphasis on automation, coupled with the ability to collect and analyze real-time data, results in a significant improvement in overall production efficiency. By combining these factors, businesses can significantly reduce costs and improve product quality.

Unleashing the Power of IoT in Smart Factories with 5G

Connecting the Physical and Digital Worlds

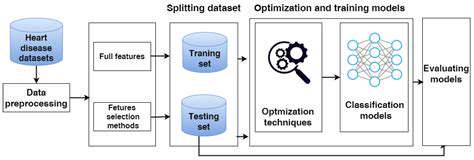

The convergence of the Industrial Internet of Things (IoT) and 5G technology is revolutionizing the manufacturing landscape. 5G's ultra-low latency and high bandwidth capabilities enable real-time data transmission, crucial for the seamless operation of interconnected machines and systems within smart factories. This allows for a deeper understanding of production processes, enabling predictive maintenance, optimized resource allocation, and enhanced operational efficiency.

Imagine a scenario where machinery can automatically report potential malfunctions before they escalate, preventing costly downtime. This proactive approach to maintenance is a direct result of the enhanced connectivity provided by 5G, facilitating the collection and analysis of vast amounts of data generated by IoT devices. This digital twin of the physical factory floor becomes a powerful tool for optimization and improvement.

Predictive Maintenance and Proactive Problem Solving

5G's low latency allows for real-time monitoring of equipment health, enabling predictive maintenance strategies. By analyzing sensor data from various machines, factories can identify potential issues before they cause significant disruptions, saving substantial time and resources. This proactive approach minimizes downtime and maximizes equipment lifespan, resulting in a more stable and efficient production process.

The ability to anticipate equipment failures is transformative. Real-time data analysis allows technicians to schedule maintenance proactively, minimizing unscheduled downtime. This proactive approach to problem-solving is a key benefit of integrating 5G with IoT in smart factories, leading to increased productivity and reduced operational costs.

Enhanced Operational Efficiency and Productivity

5G's high bandwidth enables the seamless transfer of large volumes of data generated by IoT sensors and devices. This rapid data transfer significantly improves the speed and efficiency of various processes, from automated material handling to quality control. The integration of these interconnected systems fosters a highly dynamic and responsive production environment.

By enabling real-time monitoring and control of production lines, 5G facilitates optimized resource allocation and enhanced productivity. The ability to react quickly to changing demands and adjust operations accordingly leads to a more agile and adaptable manufacturing process. This ultimately translates to improved output and reduced production costs.

Improved Safety and Security Measures

5G's reliable connectivity enables the implementation of advanced safety protocols within smart factories. Real-time monitoring of worker safety, coupled with the ability to quickly respond to potential hazards, significantly reduces the risk of accidents and injuries. Data from safety sensors can be analyzed to identify patterns and prevent future incidents.

The enhanced security features of 5G networks are critical for safeguarding sensitive data generated by IoT devices. Robust security protocols protect the integrity of factory operations and ensure the confidentiality of critical information, bolstering trust and confidence in the system. This secure data exchange is essential for building a resilient and trustworthy smart factory environment.

Optimizing Supply Chains with Real-Time Visibility

5G's robust network infrastructure enables real-time visibility into supply chain operations. Factories can track materials, inventory, and transportation in real time, enabling efficient logistics and minimizing delays. This seamless connectivity streamlines the entire process, from raw material procurement to finished goods delivery.

Real-time insights into the movement of goods across the supply chain allow for proactive adjustments to optimize delivery schedules and reduce inventory holding costs. The ability to track every step of the process provides valuable data for improving efficiency and reducing bottlenecks, ultimately leading to a smoother and more responsive supply chain management system.

Boosting Efficiency and Productivity with 5G-Enabled Automation

Enhanced Manufacturing Processes

5G's low latency and high bandwidth capabilities revolutionize manufacturing processes by enabling real-time data transmission and control of automated equipment. This allows for more precise and efficient execution of tasks, leading to reduced downtime and increased output. Imagine robots performing complex assembly operations with minimal delay, ensuring high accuracy and quality in every product. This real-time feedback loop enables predictive maintenance, identifying potential equipment failures before they occur and preventing costly production halts.

Furthermore, 5G-enabled automation facilitates the integration of various manufacturing systems, creating a seamless and interconnected production line. Data from different stages of production can be shared instantly, providing a holistic view of the entire process. This allows for optimized resource allocation and streamlined workflows, significantly enhancing overall efficiency.

Improved Supply Chain Management

5G's transformative impact extends to the supply chain, empowering businesses with enhanced visibility and control over their operations. Real-time tracking of goods and materials throughout the supply chain is now possible, providing stakeholders with a comprehensive view of inventory levels, delivery schedules, and potential bottlenecks. This transparency fosters better decision-making and allows for proactive adjustments to mitigate risks and optimize logistics.

The ability to communicate and share data instantly across the supply chain streamlines communication and reduces delays. This means quicker responses to changing market demands, faster delivery times, and reduced costs associated with inventory management. The improved visibility and control also facilitate better collaboration between partners, leading to stronger supply chain relationships.

Smart Warehousing and Logistics

5G-powered automation significantly improves warehouse operations and logistics. Imagine autonomous robots navigating warehouse environments, efficiently picking, packing, and transporting goods with precision and speed. This dramatically reduces human error, increases storage capacity, and minimizes operational costs. The real-time data generated by these automated systems provides invaluable insights into warehouse performance, allowing for optimized layout and resource allocation.

Remote Monitoring and Maintenance

5G's low latency enables remote monitoring and control of industrial equipment, allowing for proactive maintenance and minimizing downtime. Engineers can remotely diagnose issues, adjust settings, and perform maintenance tasks, even from geographically distant locations. This accessibility reduces response times, minimizes the need for costly on-site visits, and ensures continuous operation of critical machinery. Predictive maintenance, made possible by the constant stream of data from the equipment, further optimizes maintenance schedules and reduces unnecessary interventions.

5G: Paving the Way for a Future-Proof Manufacturing Ecosystem

5G's Impact on Connectivity

The rollout of 5G technology is revolutionizing how we interact with the digital world. This unprecedented level of connectivity is opening doors to entirely new possibilities in various sectors, from communication and entertainment to healthcare and manufacturing. 5G's significantly increased bandwidth and reduced latency are enabling applications that were previously unimaginable, such as real-time virtual reality experiences and remote surgery.

This enhanced connectivity is creating a more interconnected world, fostering collaboration and innovation across geographical boundaries. The speed and reliability of 5G are crucial for the seamless operation of the modern digital infrastructure.

Transforming Industries with 5G

5G is not just a technological advancement; it's a catalyst for transformative change across numerous industries. Manufacturing processes are becoming more efficient with the ability to implement real-time data analysis, leading to optimized production lines and reduced downtime. The healthcare sector is poised to experience a leap forward with remote patient monitoring and telemedicine, improving access to care and treatment outcomes.

The potential of 5G extends far beyond these two examples. Smart cities, autonomous vehicles, and the Internet of Things (IoT) are all heavily reliant on 5G's capabilities to function seamlessly and effectively.

Enhanced Mobile Experiences

Users are experiencing a significant improvement in mobile experiences thanks to 5G. Streaming high-definition video, downloading large files, and playing online games are all becoming significantly faster and more reliable. The enhanced speed and reduced latency are transforming how we consume entertainment and interact with digital content.

This seamless experience is crucial for maintaining user engagement in the digital age. The improved performance of mobile applications, coupled with the increased bandwidth, are transforming the way we use our devices.

The Future of IoT and Smart Devices

The Internet of Things (IoT) is experiencing rapid growth, and 5G plays a pivotal role in enabling its widespread adoption. Smart homes, wearables, and industrial sensors are all benefiting from the increased bandwidth and reduced latency of 5G. This technology is creating a more connected and efficient environment, impacting our daily lives in profound ways.

The integration of 5G with IoT is ushering in a new era of smart devices and connected ecosystems, providing unprecedented opportunities for automation and data collection.

5G Infrastructure and Deployment

The widespread adoption of 5G requires a robust and extensive network infrastructure. Building out this infrastructure is a significant undertaking, involving investments in new towers, antennas, and supporting technologies. This intricate process ensures the reliable delivery of 5G services to consumers and businesses.

The complexity of deploying 5G infrastructure necessitates careful planning and coordination, ensuring that the network is scalable and adaptable to future needs and technological advancements.

Challenges and Considerations

Despite the numerous benefits, 5G deployment faces certain challenges. Cost-effectiveness and equitable access remain critical considerations in ensuring widespread adoption and avoiding digital divides. Furthermore, the security of 5G networks must be a paramount concern to protect sensitive data and prevent unauthorized access.

Addressing these challenges is crucial to realizing the full potential of 5G and ensuring that its benefits are accessible to everyone. Ongoing research and development are vital in improving the security and reliability of 5G technology to meet the demands of a rapidly evolving digital landscape.