The Growing Need for Supply Chain Visibility

The Increasing Complexity of Global Trade

Globalization has significantly increased the interconnectedness of businesses, leading to intricate and complex supply chains that span multiple countries and continents. This intricate web of suppliers, manufacturers, distributors, and retailers requires sophisticated management to ensure efficient flow and timely delivery of goods. Managing this complexity necessitates advanced technological tools and strategies for effective communication and coordination across various geographical locations. The sheer number of moving parts and potential points of failure makes effective supply chain management a critical aspect of modern business operations.

The integration of diverse logistical processes, including transportation, warehousing, and inventory management, adds further complexity. Coordinating these elements seamlessly across different time zones and regulatory environments requires significant expertise and resources. This complex interplay necessitates a deep understanding of international trade regulations, customs procedures, and potentially differing cultural norms.

The Impact of Disruptions on Businesses

Unforeseen events, such as natural disasters, geopolitical instability, and pandemics, can create significant disruptions to supply chains. These disruptions can range from temporary delays in shipments to complete halts in production, causing substantial financial losses and impacting customer satisfaction. The COVID-19 pandemic, for instance, highlighted the vulnerabilities of global supply chains and the critical need for resilience and adaptability.

Disruptions can trigger cascading effects throughout the entire supply chain, affecting multiple businesses that rely on specific components or materials. This interconnectedness amplifies the impact of any disruption, making it crucial for companies to develop strategies for mitigating risks and ensuring business continuity.

Technological Advancements and Supply Chain Transformation

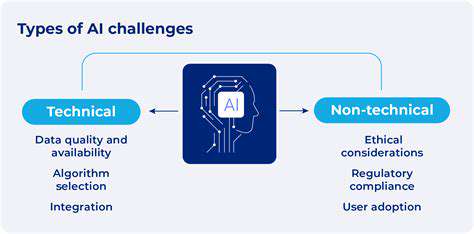

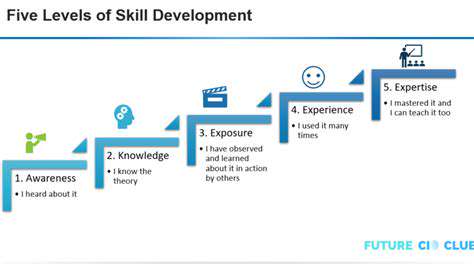

Technological advancements, particularly in areas like automation, data analytics, and artificial intelligence, are revolutionizing supply chain management. These technologies provide businesses with real-time insights into inventory levels, transportation routes, and potential bottlenecks, enabling proactive decision-making and improved efficiency. The use of data analytics allows for better forecasting and planning, reducing risks and optimizing resource allocation.

The integration of these technologies into existing supply chains allows businesses to track shipments more precisely, predict potential disruptions, and adapt to changing market demands. This enhanced visibility and responsiveness are crucial for navigating the ever-changing landscape of global trade.

Sustainability and Ethical Considerations

Growing consumer awareness and regulatory pressures are driving a shift towards more sustainable and ethical supply chains. Companies are now required to consider the environmental impact of their operations, including reducing carbon emissions and minimizing waste throughout the production process. Ethical considerations, such as fair labor practices and responsible sourcing, are also gaining prominence.

The Importance of Agility and Flexibility

Today's rapidly evolving market demands agility and flexibility from supply chains. Businesses need to be able to adapt quickly to changing customer preferences, fluctuating demand, and unforeseen disruptions. Building resilient and adaptable supply chains is essential for navigating these challenges and ensuring long-term success.

This means having the ability to quickly adjust production schedules, reroute shipments, and find alternative suppliers when necessary. Embracing innovation and technology is critical to achieving this level of flexibility and responsiveness.

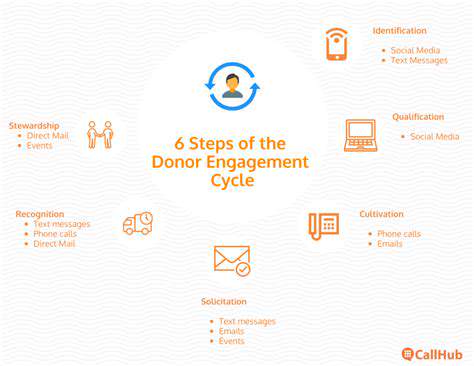

The Role of Collaboration and Partnerships

Successful supply chain management often relies on strong collaboration and partnerships between different stakeholders. This includes building relationships with suppliers, distributors, and logistics providers to ensure smooth communication and coordination throughout the entire process. Collaboration fosters trust and transparency, which are crucial for effective supply chain management.

Sharing information and resources across the supply chain can provide a more comprehensive understanding of the entire process, ultimately leading to improved efficiency and reduced risks. Partnerships allow companies to leverage each other's expertise and resources to overcome challenges and achieve shared objectives.