Predictive Maintenance: Revolutionizing Industrial Operations

Anticipatory equipment servicing represents a transformative approach to asset management, reshaping industrial practices by transitioning from failure-responsive tactics to preventative strategies. This evolution stems from improved data accessibility and sophisticated analytical capabilities. Rather than addressing equipment failures after they occur, predictive maintenance utilizes live data streams and complex algorithms to forecast potential issues and schedule interventions proactively, minimizing operational interruptions and maximizing productivity. This forward-looking methodology enables organizations to refine their maintenance schedules, eliminating unnecessary expenditures while ensuring continuous operation. The emphasis on prevention rather than reaction yields substantial financial benefits and elevated safety benchmarks.

By harnessing sensor outputs, historical performance data, and machine learning models, predictive maintenance platforms can detect subtle irregularities and patterns that signal impending equipment problems. This capability facilitates timely corrective actions, preventing expensive breakdowns and maintaining consistent output quality. This approach fosters more sustainable and robust operational environments by reducing the likelihood of unexpected stoppages and extending equipment longevity. Predictive maintenance also facilitates more strategic resource allocation, optimizing both material and human capital deployment.

Key Benefits and Applications of Predictive Maintenance

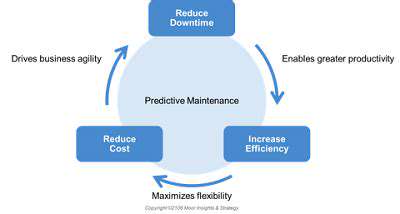

Predictive maintenance delivers advantages extending well beyond simple downtime reduction. By forecasting potential malfunctions, enterprises can dramatically lower maintenance expenses while boosting operational effectiveness. This preventative strategy permits optimized maintenance planning, decreasing production disruptions and maximizing equipment availability. The intelligence derived from predictive analytics can further enhance manufacturing processes, driving additional efficiency gains and profitability improvements.

The implementation possibilities for predictive maintenance span numerous sectors. From production facilities and power generation to logistics networks and medical institutions, predictive maintenance is redefining asset management practices. It enables early identification of developing issues, facilitating improved preventative maintenance approaches and reducing the risk of expensive failures. These advantages contribute to enhanced safety protocols, diminished environmental consequences, and superior overall operational performance.

In manufacturing environments, the ability to predict and prevent machinery failures translates to reduced operational interruptions, increased production volumes, and significant maintenance cost reductions. Similarly, the energy sector benefits from predictive maintenance through improved power plant performance and decreased catastrophic failure risks.

Transportation systems, including rail networks and aviation fleets, employ predictive maintenance to guarantee reliable and safe operations. Early problem detection prevents accidents and optimizes maintenance planning, improving both safety and cost efficiency.

Healthcare institutions utilize predictive maintenance to ensure medical equipment reliability and availability, safeguarding patient well-being and optimizing resource utilization.

IoT Sensors and Data Collection: The Foundation of Predictive Maintenance

Understanding the Role of IoT Sensors

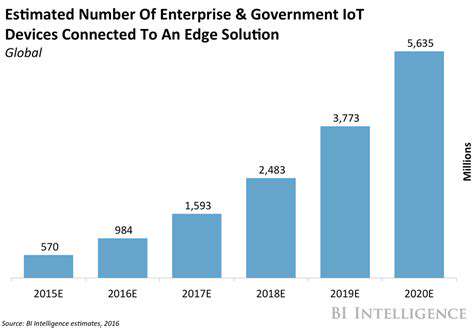

IoT sensors function as the fundamental observational components of any predictive maintenance framework. These devices meticulously track various equipment parameters, including thermal conditions, vibrational patterns, pressure variations, and structural stress. Typically embedded within machinery or strategically positioned nearby, these sensors provide continuous operational health data, creating an uninterrupted information flow essential for identifying minor irregularities that may precede major failures.

Types of Sensors Used in IoT Systems

Predictive maintenance systems incorporate diverse sensor technologies. Thermal detectors, for example, identify excessive heat buildup—a frequent warning sign of impending equipment failure. Vibration analyzers detect abnormal mechanical movements, highlighting potential bearing defects or structural vulnerabilities. Pressure monitors track fluid dynamics and system pressures, enabling early identification of leaks or pressure-related anomalies. Beyond these standard variants, specialized devices like acoustic sensors and humidity detectors play critical roles in identifying specific operational concerns.

Data Collection Methods and Strategies

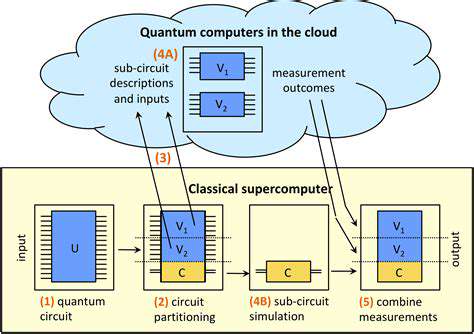

Effective data acquisition forms the cornerstone of successful predictive maintenance. This process involves selecting appropriate collection methodologies, whether wireless (utilizing Wi-Fi or cellular networks) or wired connections, depending on application requirements. Critical considerations include establishing optimal sampling frequencies, implementing data validation procedures to ensure accuracy, and employing cloud-based solutions for efficient information storage and processing. Careful attention to these elements significantly influences predictive model reliability and precision.

Data Transmission and Storage Protocols

Reliable information transfer is vital for timely analysis. Secure, efficient communication pathways must be established to transmit sensor data to central processing systems, typically utilizing cloud services or specialized industrial IoT networks. These protocols must demonstrate sufficient robustness to manage real-time data flows with minimal delay or loss. Storage solutions must offer scalability and security, capable of accommodating extensive datasets accumulated over prolonged periods.

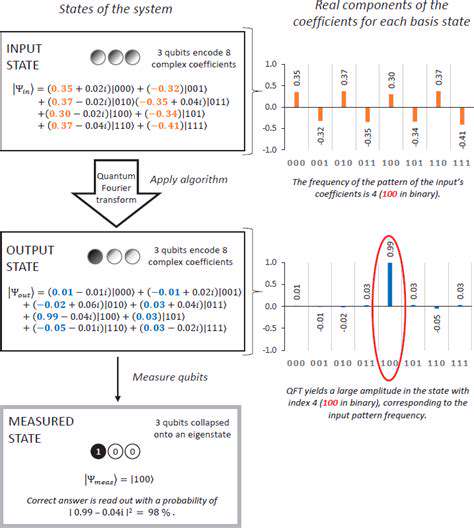

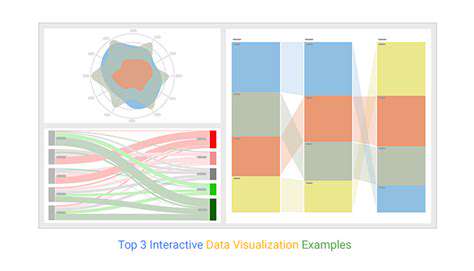

Data Preprocessing and Analysis for Insights

Unprocessed sensor data rarely provides immediate actionable intelligence. Data refinement techniques prove essential for extracting meaningful patterns, including noise filtration, handling incomplete data points, and formatting information for analytical processing. Advanced algorithms, including machine learning models, are subsequently applied to identify trends, correlations, and anomalies. These analytical processes prove indispensable for forecasting potential equipment failures and optimizing maintenance timetables.

The Significance of Real-Time Data Analysis in Predictive Maintenance

The true potential of IoT sensors manifests through instantaneous data interpretation. This capability enables immediate responses to developing situations, preventing potential equipment malfunctions. By rapidly identifying deviations from normal operation, preventative measures can be implemented, minimizing operational downtime and maximizing efficiency. Real-time analytics provide a dynamic assessment of equipment condition, facilitating proactive rather than reactive maintenance approaches, ultimately generating substantial long-term cost savings and operational improvements.