The Future of Calibration: AI Integration and Beyond

AI-Powered Calibration Systems

The integration of AI into calibration systems is poised to revolutionize laboratory equipment management. AI algorithms can analyze data from sensors, identify anomalies, and predict potential equipment failures long before they occur. This proactive approach minimizes downtime and ensures the accuracy and reliability of measurements, ultimately improving the quality and efficiency of laboratory processes. Furthermore, AI can automate complex calibration procedures, freeing up laboratory personnel for more strategic tasks.

Machine learning models can be trained on vast datasets of calibration data, enabling them to identify patterns and trends that might be missed by human operators. This allows for more precise calibration protocols, reducing variability and increasing the overall consistency of results across multiple instruments and measurements.

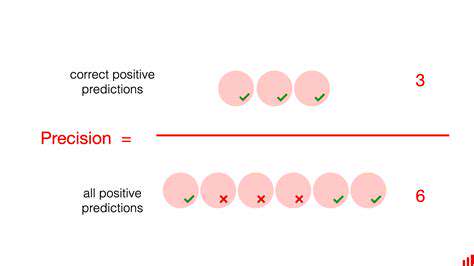

Enhanced Accuracy and Precision

AI-driven calibration systems offer significantly enhanced accuracy and precision compared to traditional methods. By analyzing data from multiple sources, AI algorithms can identify subtle variations and compensate for them, leading to more precise measurements. This improvement in accuracy translates to better quality control and reduced risk of errors in downstream applications.

The ability of AI to account for various environmental factors, such as temperature and humidity, further elevates the precision of calibration. These factors are often challenging to control in a laboratory setting, but AI algorithms can effectively compensate for these fluctuations, resulting in more reliable and accurate data.

Automated Data Acquisition and Analysis

AI significantly streamlines the calibration process by automating data acquisition and analysis. Instead of manual data entry and complex calculations, AI systems can collect data directly from instruments, perform calculations, and generate reports automatically. This automation significantly reduces the time required for calibration and frees up lab personnel to focus on other crucial tasks.

Predictive Maintenance Capabilities

A key advantage of AI in calibration is its predictive maintenance capabilities. By analyzing historical data and real-time sensor readings, AI can predict potential equipment failures, allowing for proactive maintenance and preventing costly downtime. This proactive approach to maintenance optimizes laboratory operations and minimizes unexpected interruptions.

Improved Calibration Efficiency

AI-powered calibration systems are designed to significantly improve the efficiency of the entire calibration process. Automation of tasks like data collection, analysis, and reporting reduces the time required for calibration, enabling laboratories to achieve higher throughput. This increased efficiency translates to lower operational costs and greater productivity.

Integration with Existing Lab Equipment

A crucial aspect of AI integration in calibration is its seamless integration with existing laboratory equipment. Modern AI systems are designed with flexibility and adaptability in mind, allowing for easy integration with a variety of instruments and platforms. This compatibility ensures that laboratories can leverage their existing infrastructure without significant disruptions or modifications.

Cost-Effectiveness in the Long Run

While the initial investment in AI-powered calibration systems may seem substantial, the long-term cost-effectiveness is undeniable. Reduced downtime, minimized errors, and increased efficiency translate to significant savings over the lifetime of the system. Moreover, the improved quality of data and reduced reliance on manual labor contribute to long-term cost reduction in laboratory operations.