Predictive Maintenance for Prolonged System Lifespan

Optimizing Equipment Lifespan

Predictive maintenance is a proactive approach to equipment maintenance that focuses on anticipating potential failures before they occur. This proactive strategy is crucial for extending the lifespan of equipment and preventing costly downtime. By identifying patterns and anomalies in equipment performance data, predictive maintenance enables operators to schedule maintenance tasks strategically, minimizing disruptions and maximizing operational efficiency. This approach allows maintenance teams to shift from reactive to proactive measures, significantly reducing the risk of unexpected breakdowns and associated financial losses.

A key aspect of optimizing equipment lifespan through predictive maintenance is the ability to leverage real-time data. Sensors and other monitoring devices collect vast amounts of data about equipment performance, such as vibration levels, temperature fluctuations, and energy consumption. Analyzing this data reveals subtle changes that might indicate impending failures, allowing for timely intervention and repairs. This approach enables businesses to maintain optimal performance and availability of their equipment.

Minimizing Downtime and Cost

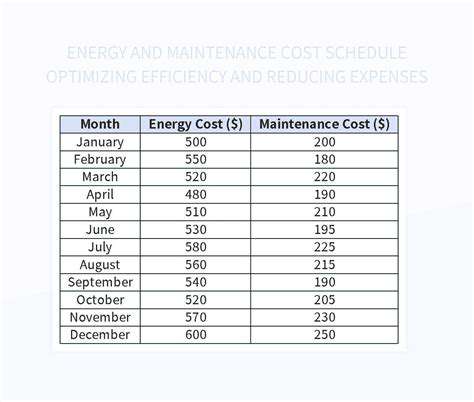

Predictive maintenance significantly reduces downtime by anticipating and preventing equipment failures. By proactively addressing potential issues, companies can avoid costly breakdowns and associated lost production time. This approach ensures that equipment is always running at peak performance, which in turn minimizes the need for unscheduled maintenance and the associated expenses.

The financial benefits of predictive maintenance are substantial. By preventing equipment failures, companies can save on repair costs, spare parts, and lost production. Predictive maintenance also reduces the risk of catastrophic failures, which can lead to significant financial losses and even safety hazards. The long-term cost savings associated with predictive maintenance often outweigh the initial investment in the necessary technology and expertise.

Implementing predictive maintenance strategies can lead to substantial cost savings over time. By reducing the frequency of unscheduled maintenance, companies can optimize their maintenance budgets and allocate resources more effectively. This approach also reduces the need for expensive emergency repairs and the potential for production losses.

Improving Operational Efficiency

Predictive maintenance is a powerful tool for improving operational efficiency. By optimizing maintenance schedules, companies can ensure that equipment is always running at peak performance, leading to increased productivity and output. This optimization leads to a more efficient use of resources and manpower.

Implementing predictive maintenance also allows for better resource allocation. Predicting equipment failures allows maintenance teams to allocate their resources more effectively, prioritizing tasks based on potential impact and urgency. This strategic approach allows for a more streamlined and efficient workflow, maximizing the overall effectiveness of the maintenance process.

By anticipating and addressing potential equipment issues, companies can improve overall operational efficiency. This approach leads to reduced downtime, optimized resource allocation, and increased productivity, ultimately contributing to a more profitable and sustainable operation. This proactive approach helps companies focus on production and other core business functions.

Enhanced Building Management System Integration

Improved Energy Efficiency

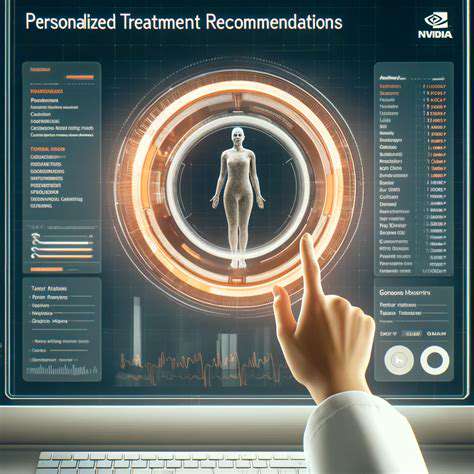

Integrating a building management system (BMS) with IoT devices allows for real-time monitoring and analysis of energy consumption patterns. This data-driven approach enables proactive adjustments to HVAC systems, lighting, and other energy-intensive components, leading to significant reductions in energy waste. Sensors throughout the building collect precise data on temperature, occupancy, and light levels, enabling the system to optimize energy use based on real-time conditions rather than pre-programmed schedules.

Furthermore, predictive maintenance capabilities within the integrated system can identify potential equipment failures before they occur, minimizing downtime and preventing costly repairs. This proactive approach not only saves money but also reduces the environmental impact associated with energy consumption.

Enhanced Security and Safety

IoT integration with a BMS provides enhanced security features. Real-time monitoring of access points, coupled with automated responses to security breaches, can effectively deter intruders and protect building assets. Sensors can detect unauthorized access attempts, triggering alarms and alerts to security personnel in real-time, improving response times and minimizing potential damage.

Moreover, IoT-enabled systems can improve safety by monitoring critical environmental parameters like temperature, humidity, and air quality. These systems can automatically adjust ventilation and air filtration to maintain safe and comfortable conditions for occupants, mitigating the risk of health hazards.

Optimized Maintenance and Repair

The integration of IoT sensors and data analytics into the BMS streamlines the maintenance and repair process. Real-time data on equipment performance, usage patterns, and potential issues allows for proactive maintenance schedules, minimizing unexpected breakdowns and costly repairs. Predictive maintenance algorithms can analyze sensor data to anticipate potential failures, enabling preventative measures to be taken before significant damage occurs, saving both time and money.

Improved Operational Efficiency

A streamlined and optimized workflow is a key benefit of enhanced BMS integration. Automated tasks, such as adjusting lighting and temperature based on occupancy levels, free up building staff to focus on other critical tasks. This efficient use of resources maximizes operational productivity and minimizes human error. The system can also automate responses to various situations, such as responding to requests for maintenance or adjusting the environmental conditions in different zones based on occupancy patterns.

Real-time Monitoring and Control

IoT sensors provide real-time data on various building parameters, enabling facility managers to monitor and control building systems remotely. Remote access allows for immediate adjustments to temperature, lighting, and security systems, regardless of location. This real-time visibility into building performance empowers facility managers to make data-driven decisions, leading to optimized resource allocation and minimized energy waste. This enhanced control enables quicker responses to issues and proactive management of building operations.

Data-Driven Decision Making

The wealth of data collected by IoT sensors and the integrated BMS provides a comprehensive overview of building performance. This data can be analyzed to identify areas for improvement, optimizing resource allocation and energy efficiency. For example, patterns in energy consumption can reveal opportunities for cost savings, while occupancy data can inform decisions about space utilization. This data-driven approach promotes a culture of continuous improvement, allowing facility managers to make informed decisions and implement strategies for enhanced building performance based on concrete data rather than assumptions or guesswork.