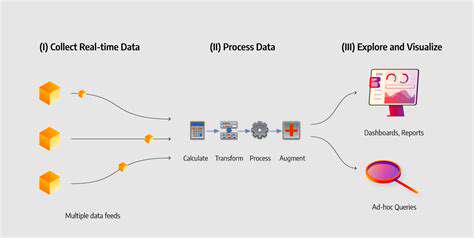

Data Collection and Analysis: The Foundation of PdM

Data Collection Methods

Effective information gathering forms the cornerstone of any meaningful examination. A well-structured methodology guarantees that collected data accurately represents the subject under study. This requires careful attention to the target group, measurable factors, and appropriate tools for information acquisition. Poorly designed collection techniques can yield inaccurate results and ultimately flawed conclusions, making meticulous planning essential.

Different investigative approaches demand distinct data gathering strategies. Quantitative research typically employs structured surveys and controlled experiments to collect numerical information suitable for statistical examination. Qualitative studies, conversely, might utilize interviews, group discussions, or direct observations to gather rich descriptive material. Choosing the appropriate method is crucial for obtaining information that aligns with research goals. Thorough understanding of the investigation's purpose is vital when selecting suitable data collection instruments.

Data Cleaning and Preprocessing

Raw information, even when collected carefully, often contains errors, inconsistencies, and missing entries. Information refinement and preparation are essential steps in ensuring data quality and reliability. This critical phase involves identifying and addressing missing data points, correcting mistakes, and transforming information into usable formats. Diligent attention to data quality prevents misleading conclusions and preserves analytical integrity.

Data preparation techniques may include multiple steps such as handling extreme values, converting data formats, and standardizing variables. These procedures often prove crucial for effective analysis, as they can substantially improve result accuracy and dependability. Properly refined and prepared information forms the basis for deriving meaningful insights. Time invested in this phase significantly influences subsequent analytical steps and contributes to research validity.

Furthermore, data transformations like normalization or logarithmic conversions can enhance certain analytical method performance. Appropriate management of missing values is equally critical to prevent analytical bias. These measures help ensure that findings remain robust and applicable across different contexts.

Data Analysis Techniques

Selecting appropriate analytical methods is essential for extracting valuable insights from gathered information. The choice depends heavily on data type, research questions, and desired outcomes. Statistical approaches including regression analysis, t-tests, and ANOVA are commonly employed for numerical data. These techniques help researchers identify patterns, relationships, and group differences.

For qualitative information, methods like thematic analysis and content examination are frequently used. These approaches help uncover recurring themes and patterns within collected material. Ultimately, the selection of analysis technique directly affects information interpretation. Choosing the right method is crucial for producing accurate and dependable results. Careful consideration of each method's limitations is necessary to ensure conclusion validity.

Information visualization plays a vital role in effectively communicating findings. Tools like charts and diagrams can transform complex data into easily understandable formats, facilitating better comprehension and insight communication. Visual representations can highlight trends, patterns, and relationships that might remain hidden in raw data tables. Visualizing information constitutes an integral part of the analysis process, enhancing research clarity and impact.

Predictive Modeling for Enhanced Aircraft Reliability

Predictive Maintenance Strategies

Predictive maintenance, a fundamental aspect of improved aircraft dependability, utilizes data analysis to anticipate potential malfunctions. By monitoring crucial operational parameters like vibration, temperature, and pressure, predictive models can detect subtle abnormalities preceding serious failures. This proactive method enables maintenance teams to schedule repairs before significant damage occurs, reducing downtime and ensuring peak aircraft performance.

Implementing predictive maintenance strategies requires careful consideration of data gathering methods and development of robust algorithms. Collected information should be comprehensive, covering various aspects of aircraft operation including flight conditions, environmental factors, and maintenance history. Advanced machine learning models are essential for extracting meaningful patterns from this data and forecasting potential problems.

Data Collection and Integration

A critical element of predictive modeling involves comprehensive collection and integration of information from diverse sources. This includes sensor data from multiple aircraft systems, maintenance records, flight documentation, and even weather data. Combining these varied information streams into a unified platform is essential for creating a complete picture of aircraft health and performance.

Ensuring information accuracy and consistency is paramount. Standardized formats and rigorous validation procedures are crucial for minimizing errors and guaranteeing reliable model predictions. Real-time data streaming capabilities are equally important for continuous monitoring and immediate response to emerging anomalies.

Machine Learning Algorithms for Anomaly Detection

Machine learning models play a central role in identifying abnormalities and predicting potential failures. Algorithms including Support Vector Machines (SVMs), Artificial Neural Networks (ANNs), and Random Forests can analyze complex datasets to detect deviations from normal operational patterns. These models are trained on historical data to learn characteristics of healthy aircraft operation and identify subtle variations that may indicate impending failures.

Selecting the appropriate algorithm depends on specific data characteristics and desired accuracy levels. The selection process requires careful evaluation of factors like data volume, quality, and complexity of variable relationships.

Improving Aircraft Safety and Operational Efficiency

Predictive modeling significantly contributes to aircraft safety by proactively identifying and addressing potential risks. By anticipating failures, maintenance teams can intervene before serious incidents occur, reducing accident probabilities and ensuring passenger and crew safety. This proactive approach also translates to improved operational efficiency.

Reduced downtime and minimized maintenance costs represent direct benefits of predictive maintenance. Scheduled repairs, coordinated with predicted failures, minimize flight schedule disruptions and optimize aircraft utilization. This results in substantial cost savings and enhanced profitability for airlines.

Model Validation and Refinement

Predictive model accuracy relies heavily on thorough validation and refinement processes. Independent testing against new data is crucial for ensuring reliability and preventing overfitting, a common machine learning issue. Continuous monitoring and evaluation of model performance are essential for maintaining accuracy and adapting to evolving aircraft conditions and operational patterns.

Feedback from field data, maintenance reports, and operational experience is vital for identifying model weaknesses and prompting improvements. This iterative process ensures models remain relevant and effective in dynamic environments.

Real-world Applications and Future Trends

Predictive modeling is already transforming aircraft maintenance practices across numerous airlines and aviation organizations. Practical applications demonstrate potential for significant improvements in safety, efficiency, and cost reduction. The technology continues to evolve, with new sensors, algorithms, and data analysis techniques emerging to further enhance predictive capabilities.

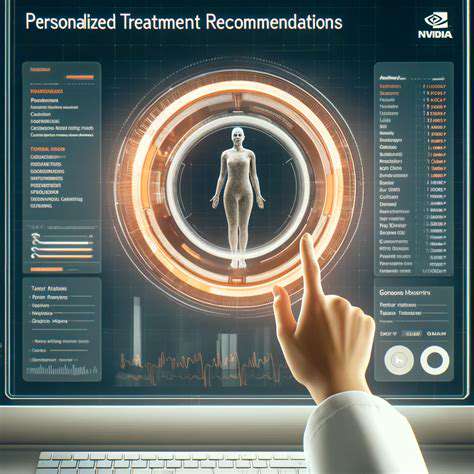

The integration of artificial intelligence (AI) and the Internet of Things (IoT) promises to revolutionize aircraft maintenance, enabling more sophisticated predictive models and proactive maintenance strategies. This progression will lead to a future where aircraft undergo continuous real-time monitoring and maintenance, ensuring optimal performance, safety, and operational efficiency.

The Future of Predictive Maintenance in Aerospace

Predictive Maintenance: A Paradigm Shift in Aerospace

Predictive maintenance, a proactive equipment care approach, is dramatically reshaping the aerospace industry. By employing data analytics and machine learning algorithms, predictive maintenance aims to forecast potential equipment failures before they happen, significantly reducing downtime and boosting operational efficiency. This transition from reactive to proactive maintenance proves essential for maintaining safety and reliability of complex aerospace systems, particularly with increasingly advanced aircraft designs.

Traditional maintenance practices often depend on fixed schedules, which can result in unnecessary servicing or, conversely, delayed interventions. Predictive maintenance, however, examines real-time data from various aircraft-embedded sensors to identify patterns and anomalies. This enables targeted maintenance actions, minimizing disruptions and maximizing operational availability.

Data-Driven Insights for Enhanced Reliability

The essence of predictive maintenance lies in extracting meaningful intelligence from enormous datasets generated by aircraft systems. This information includes sensor readings, operational parameters, and performance metrics. Advanced algorithms analyze this data, identifying trends, anomalies, and potential failure points. This analysis enables creation of predictive models that estimate equipment failure likelihood with growing precision.

The incorporation of advanced analytics technologies like machine learning and artificial intelligence into predictive maintenance systems is accelerating innovation. These technologies improve the ability to detect subtle patterns and predict potential issues with greater accuracy, substantially enhancing aerospace operation reliability and safety.

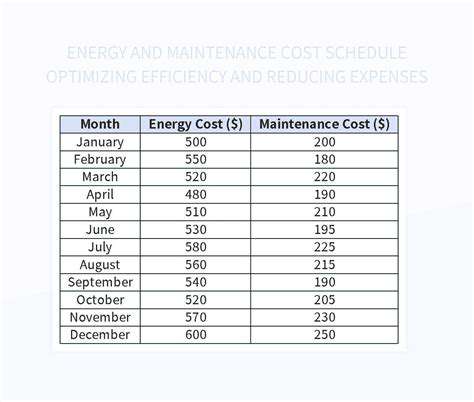

Improving Operational Efficiency and Reducing Costs

Predictive maintenance offers considerable benefits regarding operational efficiency and cost reduction. By minimizing unplanned downtime, airlines and other aerospace organizations can achieve significant maintenance cost savings and optimize fleet utilization. Reduced downtime translates to increased flight schedules, generating higher revenues and improved profitability.

The proactive maintenance approach facilitates optimization of service schedules. This means maintenance tasks are performed only when necessary, rather than following fixed intervals. This not only reduces unnecessary maintenance but also improves resource allocation, leading to additional cost savings.

The Role of IoT in Connecting the Aerospace Ecosystem

The Internet of Things (IoT) plays a pivotal role in enabling predictive maintenance in aerospace. IoT devices embedded in aircraft components collect real-time data, transmitting it to centralized systems for analysis. This continuous data flow is critical for developing and refining predictive models, allowing more accurate assessment of potential equipment failures.

Moreover, the interconnected nature of the IoT ecosystem enables seamless integration of predictive maintenance systems with other operational aspects of aerospace. This integration supports a comprehensive approach to aircraft management, optimizing various operational processes and enhancing overall performance.