Enhanced Visual Instructions and Real-Time Support

Improved Visual Communication

Modern manufacturing thrives on clarity. Enhanced visual instructions are no longer optional—they're essential for cutting errors and boosting efficiency. Gone are the days of confusing text manuals. Today, interactive diagrams, lifelike 3D models, and animated step-by-step guides projected through augmented reality (AR) interfaces transform complex procedures into intuitive visual experiences. This revolution in communication slashes training time while dramatically reducing costly mistakes caused by misinterpretation.

What sets AR apart is its ability to paint instructions directly onto the physical workspace. Imagine seeing critical components glow, watching alignment markers snap into place, or receiving instant visual confirmation for each completed step. This real-time visual dialogue between worker and machine creates an unprecedented level of precision, particularly valuable for delicate assembly tasks or intricate maintenance procedures where millimeters matter.

Real-Time Guidance and Feedback

The manufacturing floor never sleeps, and neither should support. AR transforms assistance from an interruption to an integrated experience. Workers now access expert guidance instantly—without breaking stride. The AR interface becomes a tireless mentor, highlighting each critical step as it's performed, creating a dynamic learning environment that accelerates mastery of new procedures.

When challenges arise, distance disappears. AR bridges the gap between frontline workers and expert technicians through remote collaboration tools. Complex breakdowns get resolved through shared augmented views, with expert annotations appearing directly in the worker's field of vision. This virtual pair programming for manufacturing slashes downtime and keeps operations flowing smoothly.

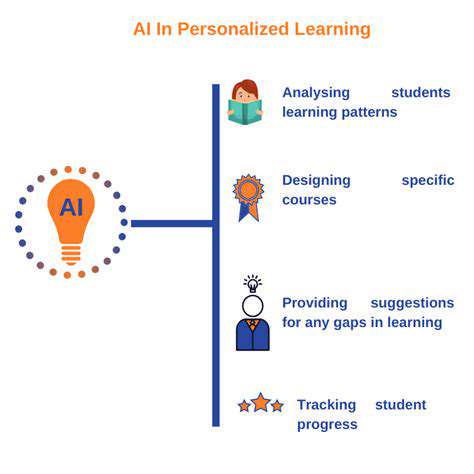

Interactive Training Modules

Training evolves from passive observation to active participation through AR's immersive simulations. New hires practice intricate procedures in hyper-realistic virtual environments—making mistakes without real-world consequences. This safe sandbox approach proves invaluable for mastering hazardous operations or complex assemblies before ever touching actual equipment.

These interactive modules don't just teach steps—they build intuition. Workers develop spatial understanding through 3D manipulation, troubleshoot simulated faults, and gain muscle memory through repeated virtual practice. The result? A workforce that transitions from training to production with remarkable confidence and competence.

Enhanced Safety and Efficiency

AR transforms safety from reactive to proactive. Potential hazards announce themselves through visual warnings before accidents occur. Critical safety protocols appear exactly when and where needed—no more forgotten steps or overlooked precautions. Machine malfunctions reveal themselves early through AR-powered diagnostics, preventing incidents before they start.

Minimizing Errors and Improving Quality Control

Minimizing Errors in Automated Robotic Systems

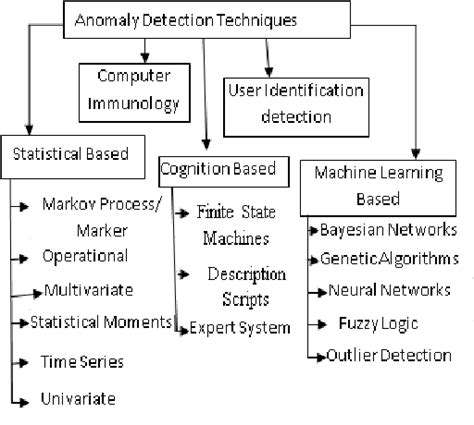

The precision dance of robotic systems demands constant vigilance. Advanced sensor networks and machine vision act as tireless quality inspectors, spotting microscopic deviations from perfection. These digital guardians work in real-time, correcting course before errors compound. Regular maintenance becomes predictive rather than reactive—addressing wear before it impacts performance.

Precision engineering meets precision programming in today's robotic arms. Every millimeter of movement gets optimized, every grip pressure calibrated. Behind the scenes, dedicated monitoring teams analyze performance data like conductors guiding an orchestra—anticipating issues before they disrupt the symphony of production.

Improving Quality Control Through Data Analysis

Modern manufacturing generates rivers of data—smart factories turn this into a quality control superpower. Sophisticated algorithms detect patterns human eyes might miss, predicting quality issues before they emerge. These digital quality guardians learn continuously, refining their understanding of perfection with each inspection.

The magic happens in the feedback loops. Every sensor reading, every robotic movement gets analyzed, creating a living blueprint of optimal performance. Quality becomes measurable, adjustable, and constantly improvable through clear dashboards that translate complex data into actionable insights.

Implementing Standardized Workflows

Consistency is the hallmark of quality. Standardized robotic workflows eliminate variability—the enemy of precision manufacturing. Every task follows meticulously documented protocols, ensuring identical results whether it's the first or thousandth iteration.

New team members benefit from this standardization, accelerating their onboarding. Clear procedures become living documents, continuously refined based on performance data and operator feedback—always moving closer to manufacturing perfection.

Utilizing Advanced Machine Vision

The robotic eye never blinks. Advanced vision systems inspect with superhuman precision, spotting imperfections invisible to human inspectors. This tireless quality control operates at production speeds, keeping pace with automated lines without becoming a bottleneck.

Proactive Maintenance and Calibration

Predictive maintenance transforms equipment care from calendar-based to condition-based. Sensors whisper warnings before failures shout, scheduling interventions during planned downtime. Regular calibration sessions keep robotic movements as precise as the day they were installed.

Training and Skill Development

Technology advances, but human expertise remains irreplaceable. Comprehensive training programs create robotic system masters—technicians who understand both the mechanics and the philosophy of precision manufacturing. These skilled professionals become the first line of defense against quality issues.

Continuous Improvement and Optimization

The pursuit of perfection never ends. Regular performance reviews, stakeholder feedback sessions, and technology audits create a culture of constant enhancement. Today's best practices become tomorrow's starting point as the organization evolves toward manufacturing excellence.

Improving Safety and Compliance

Enhanced Process Visibility

Transparency transforms safety. Augmented reality creates an x-ray vision for manufacturing processes, making every hazard and deviation instantly visible. Real-time data overlays turn complex procedures into intuitive visual flows, allowing operators to spot risks before they escalate.

Paper manuals gather dust while AR instructions live in the moment—projecting the right guidance exactly when and where it's needed. This dynamic safety net provides continuous feedback, reinforcing proper techniques and gently correcting unsafe actions before they become habits.

Streamlined Training and Procedures

AR training breaks the mold. Complex safety protocols transform into interactive experiences—workers don't just learn procedures, they live them through realistic simulations. This immersive approach etches safety consciousness deeper than any lecture ever could.

The visual nature of AR guidance creates remarkable retention. Workers remember what they've done far better than what they've read, leading to faster mastery of safety-critical procedures. Updates propagate instantly across the workforce through digital updates—no more outdated binders or confused employees working from different versions.

Reduced Errors and Improved Quality

Precision begets safety. AR guidance ensures components fit perfectly the first time, eliminating the hazards of rework. Visual tolerancing guides prevent force-fitting and dangerous improvisation. Every assembly receives digital verification before proceeding, creating multiple quality checkpoints without slowing production.

The ripple effects are profound. Fewer defects mean less hazardous rework. Clear visual standards reduce frustrating guesswork. Quality and safety become inseparable partners in the manufacturing dance, each reinforcing the other toward operational excellence.