Enabling Advanced Manufacturing Capabilities

Advanced Manufacturing Techniques

Modern production methods drive innovation across industries. These approaches incorporate diverse technologies like 3D printing, precision machining, and robotic systems that facilitate intricate, made-to-order components. They enhance productivity while cutting expenses, strengthening market positions globally.

Adopting these methods demands new equipment and staff training. However, the long-term advantages - superior quality, shorter turnaround, and adaptable production - typically outweigh initial costs.

Additive Manufacturing (3D Printing)

3D printing constructs items layer-by-layer from digital blueprints. This breakthrough enables previously unmanufacturable complex designs and customized products. It provides exceptional design flexibility and rapid prototyping capabilities.

Additionally, additive methods generate minimal material waste when creating elaborate forms. This translates to cost efficiency and environmental advantages versus conventional subtractive techniques.

Precision Machining

This subtractive process uses cutting tools to achieve exact dimensions. Such accuracy proves essential in aerospace and automotive sectors. Machining precision often determines product functionality and reliability.

Various methods - turning, milling, drilling - produce specific shapes and finishes. Selection depends on part complexity and required tolerances.

Robotics in Manufacturing

Industrial robots dramatically enhance production efficiency. They execute repetitive tasks flawlessly at high speeds, minimizing human mistakes while increasing volume. Robots excel in dangerous settings or precision-demanding operations.

Programmable robots adapt to evolving needs, providing manufacturing flexibility critical in volatile markets.

Material Science and Engineering

Manufacturing progress depends on material innovations. New substances with improved strength, resilience, and conductivity enable groundbreaking products. Customizing materials for specific uses is vital for optimal performance.

Understanding material responses during processing helps refine designs and manufacturing effectiveness, ensuring desired results.

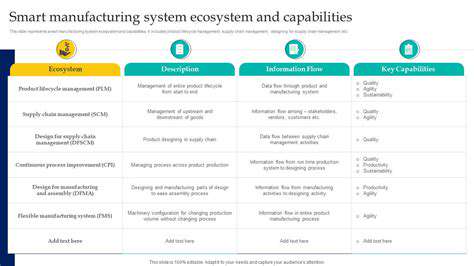

Supply Chain Management and Integration

Efficient material flows are manufacturing cornerstones. Seamless supply networks guarantee consistent component availability throughout production. This integration lets manufacturers react promptly to demand fluctuations and market changes.

Strong supplier-customer collaboration ensures smooth operations, enhancing output and business performance.

Security Considerations and Future Trends

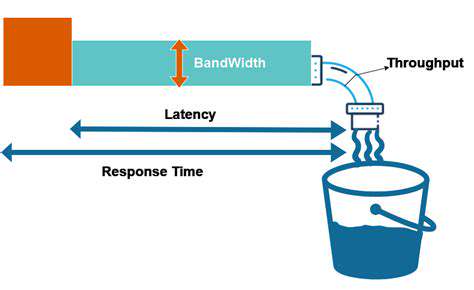

Security Considerations in Edge Computing

While edge computing reduces latency in manufacturing, it creates distinct security challenges. Edge-processed data often includes sensitive production details, equipment metrics, and proprietary designs. Safeguarding this information against breaches or manipulation is critical. Strong encryption and secure communication must protect all edge network components. A multi-layered security strategy covering hardware, software, and network configurations becomes essential.

Addressing Data Integrity at the Edge

Ensuring edge data accuracy is paramount. Compromised data can trigger faulty decisions and production flaws. Cryptographic hashes and digital signatures verify data authenticity from collection through storage. Combined with strict access controls, these measures prevent unauthorized alterations, maintaining decision-making reliability.

Future Trends in Edge Security

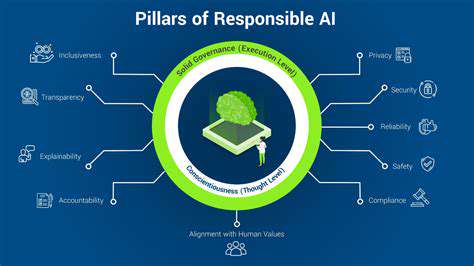

AI and machine learning will revolutionize edge security. Intelligent threat detection systems will analyze data streams instantly, spotting anomalies faster than conventional methods. ML algorithms can learn attack patterns, enabling preemptive defenses. Additionally, new edge-specific communication protocols will emerge to bolster security foundations.

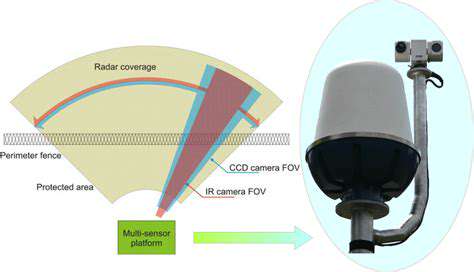

The Role of IoT Security in Edge Computing

IoT devices form edge computing's backbone in manufacturing. Securing these connected sensors and equipment is fundamental. Built-in security features must include authentication protocols, encrypted transmissions, and regular firmware updates. Comprehensive IoT ecosystem monitoring enables proactive threat prevention.

The Impact of Industrial Cybersecurity Standards

Following industry security standards strengthens edge computing defenses. Frameworks like NIST and ISA/IEC 62443 provide risk-mitigation guidelines and best practices. Compliance demonstrates security commitment while meeting sector expectations, building trust in edge infrastructure reliability.

The Future of Edge Computing in Manufacturing

Edge computing's manufacturing future depends on security evolution. Predictive maintenance and real-time control require protected data flows. As edge adoption grows, so will demand for resilient security solutions. Emerging technologies like blockchain and zero-trust models will become crucial for safeguarding industrial edge environments against evolving threats.